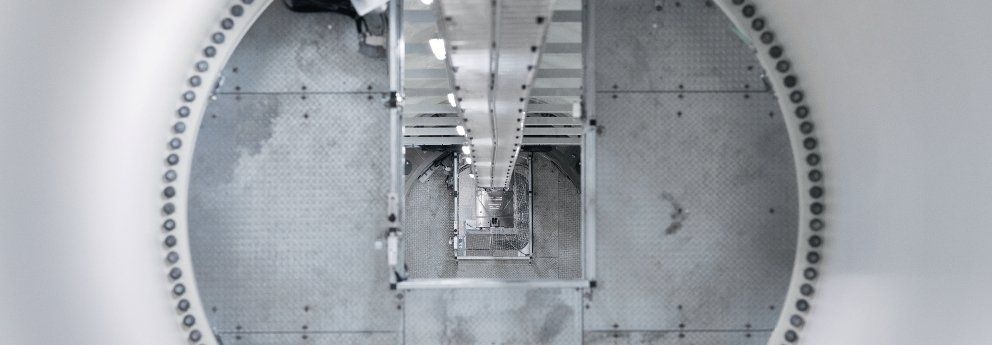

HellermannTyton specialises in cable management solutions that significantly boost the efficiency of the heavy duty systems found in wind turbines. Durability under extreme conditions is the name of the game here. Whether small wind turbines or offshore wind farms, we have been closely involved with the industry for more than a decade, giving us an in-depth understanding of what is required. We can even retrofit the right cable management system to existing wind farms.

As a result, your wind farms turbines benefit from considerably greater efficiency thanks to a guaranteed reduction in downtime and a drop in servicing and maintenance costs.

Look behind the scenes at HellermannTyton and find out what makes us tick. Our employees, who think of nothing but products and how to maximise functionality, have their say. Our cameraman decided to find out more.

To sum it up: our high level of advisory expertise, our personal attention and our bespoke products. We have been operating in the wind power sector for more than 10 years. As one of the leading suppliers of intelligent solutions for cable management, we focus on developments that can be precisely tailored to your systems. Durability is our top priority. We only use top-notch raw materials in our production processes, with stringent quality controls ensuring the reliability of our products.

Thanks to our global network of product developers, we are always able to pool core competencies from an array of sectors, thus paving the way for new solutions. You will have an entire team of experts at your service. After all, we are very much at home in the renewable energies sector, particularly wind power. This makes us a partner you can count on when it comes to the planning and installation of cable management systems in your wind turbines.

With robust cable protection, intelligent identification solutions, innovative data network technology, stable fixing systems, and sophisticated tools for the cost-saving installation of our cable management solutions, we offer an extensive range of products and services.

We never stop observing and analysing the market. New requirements necessitate new materials and innovative implementation methods in individual solutions. Wind energy moves in line with technical progress – and the competition is fierce. Therefore, the findings of our market and competitor analysis systematically inform the ongoing development of our products. What does that mean for you? It means that there are some 20,000 HellermannTyton products that are so cutting-edge that they set standards around the world. In other words, your wind turbines are in safe hands when it comes to cable management.

When working together, we strive for direct communication with our customers. That means listening, analysing and discussing. These are the key instruments with which we develop new cable management solutions. Your wind turbines can only achieve the high degree of efficiency on which your business success is measured if you benefit from fail-safe operation and cost-neutral maintenance. That’s why it’s so important for us to pinpoint your requirements. We will then rethink each relevant component, enabling us to maximise product quality. Our foes are extreme weather conditions such as cold, heat, snow and humidity, as well as the high-salt conditions in which offshore wind turbines have to generate power all year round. Working together, we can help you achieve a decisive advantage.

Our portfolio for wind turbines reflects the diversity of specialist requirements in wind energy. We analyse the technology and develop operational capability for greater safety and efficiency. At the end of the day, you benefit from greater cost-effectiveness, as our products minimise maintenance costs where it matters. What’s more, we always think one step ahead and plan holistic solutions. The reduction in cable friction achieved by HellermannTyton cable protection significantly reduces the risk of short circuits. The durability of the material makes it possible to make considerable cost savings, both in the servicing and maintenance of entire offshore wind farms and small wind turbines, thereby boosting the effectiveness of each and every unit.

HellermannTyton is on hand with 39 companies on all five continents. We offer a wealth of innovative products for the renewable energies sector – including retrofits in hard-to-access systems.

You’ve come to the right place with HellermannTyton. We will answer your specific questions – and when we develop brand-new solutions for you, they will precisely match the technological requirements found in the wind energy sector. Put us to the test – we look forward to partnering with you.

Our portfolio is vast, our love of innovation boundless; each and every product has been tested over an extended period to verify that it delivers phenomenal reliability.

Whenever the forces of torsion wreak havoc and wherever the lifespan of power cables is limited by friction, that’s where we come in with Helagaine Twist-In. If torsion arises in a bundle, the individual cables will be protected. This abrasion-proof, self-closing cable sleeve extends operational lifespan and significantly reduces repair frequency.

Helagaine Twist-In, die Helagaine Twist-In: the smart solution for wind turbines.

Reduce maintenance on existing wind farms. With the robust Helahook, we have developed a reliable cable protection sleeve that is extremely easy to retrofit. Thanks to its outstanding elasticity, it is ideal for bends and different diameters. Installation is a breeze, and service technicians can reopen Helahook at any time.

Reduce maintenance on existing wind farms. With the robust Helahook, we have developed a reliable cable protection sleeve that is extremely easy to retrofit. Thanks to its outstanding elasticity, it is ideal for bends and different diameters. Installation is a breeze, and service technicians can reopen Helahook at any time.

Time is money, especially where installation is concerned. Based on our core competency, the T- and X-Series are amongst the most economic cable tie solutions. Thanks to universal deployment within the nacelle and binding with our precision tensioning tools (such as the EVO7), it is possible to install the ties in a highly streamlined manner. The unique shape simplifies the looping process and enables speedy working. Furthermore, the durability of the material helps to cut maintenance costs. More on the T-Series here.

Time is money, especially where installation is concerned. Based on our core competency, the T- and X-Series are amongst the most economic cable tie solutions. Thanks to universal deployment within the nacelle and binding with our precision tensioning tools (such as the EVO7), it is possible to install the ties in a highly streamlined manner. The unique shape simplifies the looping process and enables speedy working. Furthermore, the durability of the material helps to cut maintenance costs. More on the T-Series here.

Our SPF spiral bindings offer an extraordinary level of protection. The rounded edges and the heavy walled material deliver outstanding mechanical protection and conduction stability. Having proven their mettle in the petrochemical industry – where their excellent resistance against oil is much appreciated – they can also be used in the wind energy sector to boost efficiency by reducing the maintenance of cable systems.

Our SPF spiral bindings offer an extraordinary level of protection. The rounded edges and the heavy walled material deliver outstanding mechanical protection and conduction stability. Having proven their mettle in the petrochemical industry – where their excellent resistance against oil is much appreciated – they can also be used in the wind energy sector to boost efficiency by reducing the maintenance of cable systems.

Where temperature fluctuations and humidity put a strain on materials, HellermannTyton is on hand to safeguard your cable systems with innovative countermeasures. Our SA47-HT heat shrinkable tubing has a special thermoplastic adhesive liner with a high melting point. As a result, the SA47-HT not only offers corrosion protection, but also snuggles around your cables to provide a stable and watertight sheath. The result is exceptional moisture protection.

Where temperature fluctuations and humidity put a strain on materials, HellermannTyton is on hand to safeguard your cable systems with innovative countermeasures. Our SA47-HT heat shrinkable tubing has a special thermoplastic adhesive liner with a high melting point. As a result, the SA47-HT not only offers corrosion protection, but also snuggles around your cables to provide a stable and watertight sheath. The result is exceptional moisture protection.

The SA47 heat shrinkable tubing range offers such excellent corrosion protection that it even meets the exacting demands of the automotive industry – another good reason to incorporate them into your wind turbine.

The SA47 heat shrinkable tubing range offers such excellent corrosion protection that it even meets the exacting demands of the automotive industry – another good reason to incorporate them into your wind turbine.

Discover further information here.

Cable management solutions that are sophisticated in every detail, coupled with high-performance tensioning tools, have been our core area of expertise for decades.

We have developed a range of specialist solutions for wind turbines. For instance, we know the expenses associated with repair work and routine maintenance in tight spaces and under challenging conditions. It all costs time. With highly flexible cable protection products that can always be opened and resealed, you can significantly reduce your service units. And when it comes to retrofitting a significantly more durable cable protection solution in a long-established wind farm, we make it possible – without the costly dismantling of diverse components.

Whether we’re talking about individual wind turbines or entire offshore wind farms, our products are designed to maintain – and even boost – the efficiency of your site This goes far beyond an optimised lightning protection system and the effective safeguarding of complex cable bundles. We also accept challenges that are out of the ordinary, such as the critical cabling for those sensitive sensors inside the rotor blades that are needed to reduce noise emissions. By drawing on this and the many other engineering services we offer, you will increase the efficiency of your wind turbines – because the durability of heavy duty systems translates into hard cash.

Working with us will also illustrate another aspect of efficiency. Because HellermannTyton is a one-stop shop for all the products you need, it’s possible to streamline project management and processes during the planning and construction of your wind turbines. The supply chain can be kept to a bare minimum, procurement costs are reduced, and resources are optimised in a highly efficient manner.

Thanks to a comprehensive network of service-oriented branches and expert distribution partners, we can guarantee you the same outstanding service level across the globe. And with our renowned flexibility, fast response times, and immediate deliveries, we can give you the level of planning reliability that is so important in the renewable energies sector.

We know how important it is that wind turbines stay highly effective over the long term. We also have a raft of technological condition monitoring solutions that can be seamlessly incorporated into your network infrastructure. The complex nexus of sensor units and other monitoring systems found in each individual wind turbine has to ensure smooth operation by means of stable, real-time signal transmission and processing. A fibre optic cable with the requisite bandwidth carries the signals to a data centre at the wind farm control unit – often covering great distances.

HellermannTyton offers outstanding products in this area. Alongside sophisticated cable management solutions, we stock splice sleeves for fibre optic cables and specially developed connection modules to enable you to link your turbines in a cost-saving manner using fibre-optic cables. Our products have been tested in practice for many years, and our portfolio includes numerous sizes and assembly options, thus enabling us to respond to your individual requirements with bespoke solutions. The fibre optic cables are enclosed in systematically installable modules to save space. This not only simplifies and speeds up cable installation, but allows you to successively expand capacity at any time. So as you can see, the future has already been built in to HellermannTyton products.

How about our patented Cablelok system? Here, the old adage ‘time is money’ really pays off. Instead of conventional heat shrinkable tubing, HellermannTyton Cablelok is used for the durable sealing of sensitive fibre-optic sleeves, which can reduce installation time by up to 90 per cent.

Our RapidNet innovation also follows the imperative of speedy installation. Thanks to specially developed, prefabricated point-to-point connections made using fibre optics and the latest copper technologies, this modular system minimises installation times, enabling you to build your wind farm control unit at a lower cost. And you save the most valuable asset of them all: time.

A wind farm with electrical substation is like a living organism and places high demands on the network infrastructure. It is necessary to monitor this organism’s vital signs using sensors and transfer this information, which includes data recorded about the gearbox, the power train and the mechanical load on the structure. Also transmitted is information on the condition and performance of the rotor blades, along with data recorded on external factors, such as temperature, wind speed and wind direction. All these signals have to be transmitted to the wind farm control unit in a coordinated manner and without data loss.

Only durable materials, coupled with precise and stable workmanship on cable installation parts, can provide the safety benefits necessary to ensure that electricity can be fed in to the grid and sensitive control systems be remotely monitored and operated without error and with a low level of maintenance.

Only durable materials, coupled with precise and stable workmanship on cable installation parts, can provide the safety benefits necessary to ensure that electricity can be fed in to the grid and sensitive control systems be remotely monitored and operated without error and with a low level of maintenance.

Heavy cabling requires unique solutions. Our heavy duty parts, such as specially developed heavy duty mounts for cable ties, can be incorporated into existing screw connections. As a result, it is easy to lay cables in a way that is appropriate for the turbine or make use of existing bolts, especially when it is necessary to guarantee a particular load-bearing capacity.

Originally developed for heavy construction machinery and designed to hold cables, pipes, and pressure tubes in place under extreme conditions, our heavy duty parts are perfect for wind turbines on account of their unique properties.

The world of renewable energies has its own set of rules and we play by them with each one of our protected cable systems.

The requirements are as complex as they are diverse. Harnessing our twin passions for innovation and service, we have developed outstanding cable management solutions for wind turbines. And as a global manufacturer with 35 companies on five continents, we are in a position to develop truly bespoke concepts to meet your individual needs. And we focus solely on your main aim: efficiency.

Wind farms base their claim to legitimacy on their high degree of effectiveness and, with every optimisation made – such as each significant reduction in maintenance costs – the number of efficient turbines keeps on growing. With this in mind, we continually break new ground as we develop bespoke protection for critical areas of application.

One of the results is our sophisticated range of heavy duty parts. Wherever the dead weight of pipes and cable harnesses in offshore wind farms and on small wind turbines necessitates strong connections, we offer strong heavy duty mounts that you can rely on.

HellermannTyton heavy duty parts can even be installed in existing screw connections. And because we know that every minute counts in the time before a wind turbine goes on to the grid, our heavy duty parts can be mounted with a high level of turning torque.

On-site technicians benefit from the convenience of being able to position the screw connection as normal. And as the technician is finished more quickly, the process is more cost-effective for you.

Consider the following situation: a new wind farm is built but, after a while, it becomes clear that enhanced cable protection is the only way to minimise downtime. It is necessary, however, to disassemble numerous elements to get to the heart of the problem – and that costs money. But fear not. We can also help boost efficiency here: with a unique cable protection solution that can be retrofitted to existing turbines without incurring large costs. Our engineers thrive on this kind of challenge – and it’s what we are all about. And because we always think one step ahead, our specialist cable protection is built in such a way that it can be applied and removed any number of times, reducing both maintenance times and material use.

Identification systems from HellermannTyton help your servicing technicians safely navigate their way through all points in a complex cabling and piping structure. What’s more, our identification tags are quick and easy to create and attach. Take our TIPTAG labels, for instance, which have been developed for continuous strain under extreme conditions. They are ideal for larger-diameter pipes for drive systems, as well as hydraulic tubing and power cables. It also goes without saying that TIPTAG labels can be retrofitted. We recommend our self-laminating labels for a robust identification system that can be quickly understood. They are made for safe use under extreme conditions in environments where temperature fluctuations and high moisture levels are the order of the day. A sturdy protective laminate ensures that your identification system can withstand external influences.

Furthermore, these special labels can be printed on all common printer systems. The cabling can be labelled by hand in next to no time thanks to these self-laminating labels, saving both time and resources – and bringing us back nicely to the topic of efficiency.

Print straight onto shrinkable tubes and quickly and easily fill in labels: the TT4000+ thermal-transfer printer from HellermannTyton can handle even large print volumes quickly and reliably. Its robust and compact design makes it perfect for universal use.

Print straight onto shrinkable tubes and quickly and easily fill in labels: the TT4000+ thermal-transfer printer from HellermannTyton can handle even large print volumes quickly and reliably. Its robust and compact design makes it perfect for universal use.

The right software for your identification systems gives you independence and makes it possible to produce professional labels in a speedy fashion. TagPrint Pro will boost your performance even further and can even be used to create complete identification signs and cable laminator. Even marking shrinkable tubing is a piece of cake for TagPrint Pro.

The right software for your identification systems gives you independence and makes it possible to produce professional labels in a speedy fashion. TagPrint Pro will boost your performance even further and can even be used to create complete identification signs and cable laminator. Even marking shrinkable tubing is a piece of cake for TagPrint Pro.

Labelling with 1204 type labels eliminates the costly use of materials associated with the standard but expensive aluminium plates. The matt, sliver-coloured 1204 labels are perfect for the production of special type labels for flat and level surfaces, such as on device housing and switch cabinets. Thanks to the wide selection of formats, you retain a great deal of flexibility in terms of labelling and can create individual solutions at any time. The adhesive used by HellermannTyton is ideal for critical surfaces such as paints and plastics. The enormous temperature stability of up to +150 °C makes these labels suitable for a vast array of applications.

As you can see, we can respond to any requirements with the right identification system. Whether quick and flexible cable labelling by hand, printable shrinkable tubing or industrial permanent identification, we are a partner you can count on in this area thanks to our high-quality industrial identification solutions.

At what point does bespoke cable management boost the efficiency of wind turbines? How can your systems reduce the number of short circuits in the long term and at what relevant points can we help you achieve greater efficiency? Discover the key trends here and learn all about innovations connected to cable management solutions.

Alongside photovoltaic installations and hydroelectric power stations, wind farms are one of the main sources of renewable energy in Germany. Therefore, ever greater demands are being placed on wind turbines in terms of performance and reliability. A standard modern wind turbine generally supplies between 1.5 and 4 megawatts of nominal capacity (MW), with offshore models delivering up to 8 MW. As the rotor blades always have to face the wind in order to generate electricity efficiently, the strain on the power cables is enormous.

Alongside photovoltaic installations and hydroelectric power stations, wind farms are one of the main sources of renewable energy in Germany. Therefore, ever greater demands are being placed on wind turbines in terms of performance and reliability. A standard modern wind turbine generally supplies between 1.5 and 4 megawatts of nominal capacity (MW), with offshore models delivering up to 8 MW. As the rotor blades always have to face the wind in order to generate electricity efficiently, the strain on the power cables is enormous.

The cables are subject to constant torsion, primarily in terms of their loop shape. With the cable grips usually used for mounting, this can lead to individual wires breaking. We ensure that the insulation of adjacent cables in the wind park remains undamaged. Find out more in our blog.

Electrical short circuits have the potential to wreak havoc. The risk of injury and damage to the surrounding area caused by flailing cables is extremely high, especially when single-core power cables are laid in trefoil formation.

Electrical short circuits have the potential to wreak havoc. The risk of injury and damage to the surrounding area caused by flailing cables is extremely high, especially when single-core power cables are laid in trefoil formation.

Cable cleats are a common way of securing low- and medium-voltage cables in electrical industrial installations, in rolling stock, in the mining industry and on the high seas.

Manufacturers have to keep the cost of their product components as low as possible if they are to survive on the global market. Many companies, however, make their own components, even though the right parts can often be bought more cheaply. By providing free CAD data (including 3D previews), HellermannTyton enables engineers to find the right solution for their construction project.

We are in a strong position. Across the globe, 3,800 skilled HellermannTyton employees work to develop innovative cable management solutions. Our aim is to boost your commercial success. Our methods involve securing your cable systems and optimally routing them through your turbines, with bespoke solutions, durable materials and fast installation techniques reducing costs by a significant amount. Everything works together in harmony to slash maintenance costs.

When customer-specific requirements only leave room for a bespoke solution, we are your first port of call. After all, HellermannTyton is renowned for its ability to develop customised products, which we do in partnership with you – from the concept development phase through to application training and beyond. Only in this way can the best ideas fitted precisely to the application-specific technologies that take your business forward. The reliability of the tiniest parts is of crucial importance when it comes to wind turbines. Cost of energy is the rule that comes above all else – and serves as our yardstick too. The efficiency of your turbines takes top priority throughout our planning and implementation work.

Talking about success isn’t easy, but we’re going to do it anyway. That’s because HellermannTyton has a maxim that has shaped the company’s success for many decades: ‘avoid downtime and go the extra mile where others stop.’ We transform innovations into revolutionary products, time after time. Because if your wind turbines are running like clockwork, then we know we’ve done a great job.

The story of the PMB5 paste adhesive mount is a prime example of the restlessness of our engineers and developers, who have no intention of settling for the status quo. Originally, the mount comprised four components. Every time, a metal base plate, a separator and a cable socket had to be elaborately held together with a screw. Paste adhesive was then applied at the point of installation. This lengthy installation process was a bugbear for our developers and, a short while later, the first designs for the PMB5 were submitted.

The story of the PMB5 paste adhesive mount is a prime example of the restlessness of our engineers and developers, who have no intention of settling for the status quo. Originally, the mount comprised four components. Every time, a metal base plate, a separator and a cable socket had to be elaborately held together with a screw. Paste adhesive was then applied at the point of installation. This lengthy installation process was a bugbear for our developers and, a short while later, the first designs for the PMB5 were submitted.

This was followed by plenty of tinkering and testing. The solution from HellermannTyton: a single component made from special high-strength plastic that is quick to install, light as a feather and corrosion-proof.

Why settle for three components that give you one benefit when you can have one component that gives you three? That’s how we think here at HellermannTyton. And there’s no denying that we’re quite proud of the result.