No cable can meet the demands posed today in terms of abrasion resistance, tensile strength and form consistency or impact resistance without having appropriate cable protection. Wire conduits have to meet these demands and also provide protection against dirt and dampness or resistance against extreme temperature loads.

From excellent flexibility, to high flame-retardant properties to exceptional mechanical protection, thick-walled or thin-walled, HellermannTyton guarantees the highest quality and safety in all cable protection areas. Wherever cable protection is needed, there are unique requirements. Whilst cable protection in plant and machinery construction requires high levels of mechanical impact resistance and abrasion resistance, a wire conduit or braided sleeving used in public buildings or in rolling-stock must meet the highest fire safety standards and needs to be halogen-free.

In addition to the outstanding material properties of the flexible cable protection conduits from HellermannTyton, customers also benefit from system solutions. For each metallic or non-metallic cable conduit in the HelaGuard series, there are a number of accessories available, for example:

Whether construction or retrofitting, for example with braided sleeves that can be re-opened or closed, find the right cable protection solution for your application now.

The requirements in the field of cable protection are becoming increasingly complex. Wire conduits need a lot of features to protect cable bundles optimally under diverse conditions, e.g.:

HellermannTyton is a global manufacturer that offers high-performance market solutions that uniquely meet the needs of customers, no matter what industry they operate in. Key aspects include solving a specific requirement, saving installation and component costs and improving the quality of the end product.

The product portfolio includes following solutions:

An comprehensive range of flexible protection conduits made of PA6, flame retardant PA6-FR, PA12 and PP, as well as the double-slit flexible conduit HG-DC suitable for retro-fitting. A complete range of IP66 and IP68/IP69k glands in a wide variety of shapes (straight, 90°, 45°, T, Y and flange), with fixed metric and PG threads, or alternatively with external or internal swivel brass threads. Fittings with strain relief and cable sealing are also available.

General purpose flexible conduits (galvanised steel and stainless steel SS316) with high compression, tensile and impact strength. Nickel plated brass and stainless steel (SS316) fittings (metric and PG) with fixed and external threads.

Flexible metallic PVC conduits, PA6 and polyolefin (PO) covers and very strong compression, tensile and impact strength. Nickel plated brass IP54 fittings (metric and PG) as well as IP65 compression fittings (metric and PG) with excellent pull-off strength. Both versions in various shapes and with fixed or swivel threads.

Flexible metallic conduits with smooth PVC and thermoplastic rubber covers and high compression, tensile and impact strength. Nickel plated brass IP68/IP69 compression fittings (metric and PG) with excellent pull-off strength. The protective conduit systems are suitable for outdoor use.

Extremely flexible PVC conduits with rigid-PVC spiral reinforcement with smooth inner bore (PSRSC conduits also with smooth outer cover). Fittings include straight and 90° PA66 fittings (IP66 and IP67), straight and 90° nickel-plated brass fittings (IP66, IP67, IP68 and IP69k) and straight and 90° stainless steel (316) fittings (IP66, IP67, IP68 and IP69k).

A wide assortment of clips, couplings, locknuts, sealing washers, endcaps and thread converters for use with HelaGuard cable protection conduits.

Highly flexible conduits made of high-grade PVC and a plastic-coated spring steel wire. IP54 fittings with metric and PG threads or alternatively with a mounting bracket. FlexiGuard is typically used to protect wires to switching equipment and in plant construction.

CTT NSA 935805 compliant PTFE protection conduits with excellent resistance to almost all chemicals as well as to low and high temperatures, very good tensile strength and very good fatigue life. The CTT conduits made of PTFE protect wires from extreme temperatures, fire, moisture, corrosion, vibration and abrasion.

The Helawrap cable protection system is the ideal solution for bundling and protecting cables and wires. The Helawrap applicator tool enables the user to bundle cables rapidly and effortlessly. Thanks to the Helawrap accessories, Helawrap tubing can be fixed on tables and cupboards.

Protection spiral binding is used to organise and protect wires and hoses. HellermannTyton spiral binding is available in a wide range of diameters, colours and materials.

Cable protection wiring ducts are used in wiring panels and switching systems. HellermannTyton offers rigid protection ducts made of PVC as well as from halogen-free PC/ABS. Furthermore, accessories for fixing ducts and DIN-Rails are available.

Rigid conduits are used in wiring panels and switching systems. HellermannTyton offers cable trays made of PVC as well as from halogen-free PC/ABS. Furthermore, accessories for fixing ducts and DIN-Rails are available.

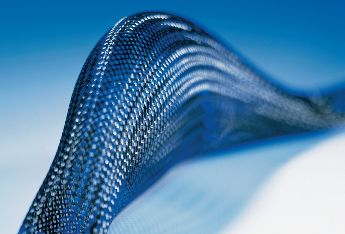

Cable protection braided sleeving made from Polyamide 6.6 (PA66) and Polyester (PET), also combined with tin-platted copper for EMI-shielding, protects wires from abrasion. Helahook fabric protection tubing hook-and-loop seal can be retro-fitted and re-opened and closed repeatedly. The self-closing cable protection sleeve Helagaine Twist-In is ideal abrasion protection even on pre-installed components.

EdgeGuard PVC edge protection strip used on straight sharp edges. Flexiform edge protection strip is made from Polyethylene (PE), Polyamide (PA) or Polytetrafluoroethylene (PTFE) and is used to protect cables routed through sharp-edged cut-out sections.

Bend protection grommets, edge protection grommets, strain relief grommets, push-on caps and elbow grommets for a large varity of diameters and purposes.

The corrugated pipe HG-SW provides very good resistance to abrasion, compression and impact, is highly flexible and has a long fatigue-life. It is also very resistant to solvents and oils and is free of halogen, sulphur and phosphorous.

Preferably used in following industries:

The light weight HG-LW cable protection conduit is very fleixble with a small bending radius. It has a long fatigue-life and provides good resistance to abrasion, compression and impact. It is also very resistant to solvents and oils and is free of halogen, sulphur and phosphorous.

Preferably used in following industries:

The ideal solution, wherever lower mechanical protection is required.

The extremely flame-retardant cable protection conduit HG-FR including EN45545-2 certification has low smoke and toxicity, is very flexible and has a long fatigue-life. The protection conduit is also resistant to abrasion, compression and impact. It is also very resistant to solvents and oils and is free of halogen, sulphur and phosphorous.

Preferably used in following industries:

The ideal solution, where high fire protection is required.

The double slit corrugated HG-DC cable pipe can be open and closed repeated and offers excellent abrasion resistance. Cables are easily inserted laterally. The conduit is resistant to abrasion, compression and impact. It is also very resistant to solvents and oils and is free of halogen, sulphur and phosphorous.

Preferably used in following industries:

The ideal solution, wherever retrofitting is required.

The SC galvanized steel cable conduit offers very excellent compression, impact and tensile strength and is very flexible.

Preferably used in following areas:

The ideal solution, when strong mechanical protection is required.

The SSC stainless steel cable conduit is very resistant to rust and corrosion, is flexible and offers very good compression, impact and tensile strength.

Preferably used in following areas:

Commonly used in hospitals and clinics, particularly in corrosive environments.

The PCS galvanised steel cable conduit with PVC cover offers very good compression, impact and tensile strength, is very flexible and is resistant to alkalis, acids and chemicals.

Commonly used in machines and plants.

The LTS galvanised steel cable conduit with smooth, liquid-tight PVC cover (IP68, IP69 with LTS fittings) offers very good compression, impact and tensile strength, good flexibility and is resistant to oils, greases, acids and chemicals. It is suitable for outdoor use.

Commonly used in machine tools or outdoor installations and wherever liquid tightness (IP68) is required.

The braided sleeving HEGMAN and HEGMANWO are made of meta-aramid NOMEX®. They are flexible and their high expanision rate allows for easy installation even over long lengths and connectors.

The braided sleeving HEGMAN and HEGMANWO offer optimal mechanical protection for harnesses and can withstand the most severe environments. They protect cables and wires from abrasion, high temperatures and flames.

The cable protection HelaGaine Twist-In is a self-closing sleeve. The self-wrapping feature allows for easy, quick installation and removal of the sleeving even on enclosed components and wires.

HelaGaine Twist-In gives quick and easy access to hoses and wires for inspection, maintenance and assembly at any time. It covers a wide range of uses and diameters with a small range of sizes.

HelaGaine Twist-In is available in three different designs:

Helagaine HEGP braided sleeving offers flexible cable protection, high abrasion resistance and ease of application. Helagaine braided sleeves are specially woven to expand when compressed and contract when pulled.

HEGP provides a high level of surface coverage as well as a high rate of expansion for easy slip-over application. To achieve an optimal fit, it is available in 13 different sizes for diameters from 1mm to 66mm.

Helagaine HEGP braided sleeving is used in the automotive industry and in machine construction. These tubes are also used for smaller electrical appliances to avoid pockets of high temperature.

Made of tin-plated copper and polyester threads, Helagaine HEGEMIP cable protection sleeving braided sleeving offer electromagnetic (EMC) protection as well as secure cable bundling.

The supporting inner tube makes insertion of wires easier and protects the sleeves from deformation during transport. Besides their excellent electromagnetic protection ratings, they are very resistant to abrasion. Both sleeves fulfil the requirements of the international EMI norm CISPR25 (10KHz to 1GHz).

Helagaine HEGEMIP electrical conduit is used to protect highly sensitive electronics in industries, such as:

The mix of materials makes the sleeving expandable and easy to apply. In contrast to purely copper braids, these sleeves can be bent and twisted and still return to their original form. As a result, they are particularly suitable for applications where there is movement.

SPS cable protection spiral binding is very robust and offers very good protection against mechanical stress and oils. Additionally SPS spiral binding is very abrasion resistant. It is available with much larger diameters (up to 50 mm) than other spiral binding and is ideal for larger cable bundles.

SPS spiral binding is especially suitable for use in areas where high abrasion resistance and much larger cable diameters are needed, for example:

Flexiform edge protection is applied to the panel edge and is easily installed without the need for adhesives. The close-fitting profile protects cables effectively by preventing chafing.

Flexiform edge protection is used to protect cables routed through sharp-edged cut-out sections.

The Heladuct Flex flexible cable supports are a space-saving wiring system which holds the routed cable clearly open to view. Cables can be routed in or out over the whole length of the support. The supports can be rapidly mounted either with screws or an adhesive strip.

The premium foam bonding layer smooths over irregularities in the underlying surface and works particularly well on powder-coated surfaces. Due to their flexibility, it is possible to install the supports at angles of 90° and higher.

Heladuct Flex is commonly used in switching cabinets. They are also used in the furniture industry, where cables need to be routed rapidly and attractively.

Cable protection is used to safeguard cables from mechanical damage, environmental hazards, and accidental interference. Implementing cable protection measures helps ensure the integrity, longevity, and reliability of cable systems. Cable protection can be applied to different kinds of cables and there are several methods of cable protection available such as physical protection (trays, conduits, and ducts), routing and support (trays, cable ties, clamps, and brackets).

Overall, cable protection is important for maintaining reliable and safe operations, prolonging cable lifespan, reducing downtime, and protecting data and communication systems. It is an essential aspect of infrastructure design and maintenance across various industries.

Cable protection is beneficial in a wide range of industries where cables are used for power transmission, data transmission and overall communication infrastructure. This includes the following: construction and infrastructure, power generation and distribution, telecommunications and data centers, oil and gas, manufacturing as well as the transportation sector.

Cable protection systems are designed to provide physical protection against various environmental factors that can harm cables, including moisture, chemicals, oils, corrosive substances, mechanical stresses, and extreme temperatures. Corrosive environments, such as coastal areas with high salt content or chemical processing facilities, require cables to be protected in order to prevent degradation over time. In such scenarios, cable protection solutions made of materials resistant to corrosion, such as stainless steel or PVC, are commonly used.

It is important to exercise caution when removing cable protection to avoid damaging the cables or any underlying components. Safe cable protection removal will depend on the specific type of protection in place. To remove cable sleeves for example, simply unfasten any velcro or adhesive closures and slide the sleeve off the cables. To remove cable conduits, you will need to unfasten any brackets or clips holding them in place and then slide the conduits off the cables.

Protecting cables against rodents is essential to prevent damage and safety hazards. Rodents, such as rats and mice, have a natural tendency to gnaw on various materials, including cables, which can lead to costly repairs or disruptions in services. To prevent this, you can take the following measures: