Thermal transfer printers use heat and ribbons to produce long-lasting print results with high resolution up to 300 dpi. Texts, logos and barcodes can be printed as well as information from Excel databases. The range of printable materials includes heatshrink tubing, cable markers and industrial labels.

All HellermannTyton printers are optimized for use in industrial environments. Thanks to up to 300 meters of ribbon length, there is less standstill due to downtime. And costs associated with ribbon refills and production changeovers are minimized.

Our thermal transfer printers are not only robust and powerful, they are also versatile.With the built-in network driver and automation capabilities, you can control multiple printers from one source. Above all, our printer solutions are easy to use: select from stored print designs via the user interface or create your own templates.

The TT431 is the ideal entry-level model: perfectly suited for small to medium print volumes for all standard applications such as printing bar codes, warning symbols, logos and text. The TT431 is very easy to set up like it’s predecessor model shown in this short tutorial video below.

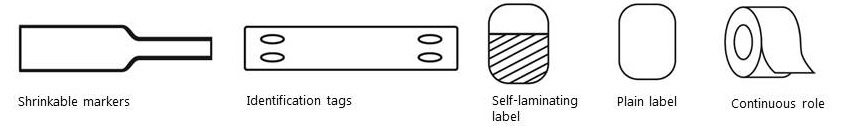

Possible materials that can be used for printing with the TT431:

One of the most important aspects of this printer is: user-friendliness. The TT431 can be easily and conveniently transported from workstation to workstation thanks to its low weight and compact design.

In addition, printing is easier than ever before: especially thanks to the 4.3-inch colour touch display, which allows uncomplicated and intuitive working with the printer – including clear status messages.

But it's not just printing that's user-friendly, thanks to TagPrint Pro 4.0 software, marking design is also extremely convenient.

Benefits at a glance:

Useful add-on: The optional cutter and perforator make this printer ideal for a wide range of applications.

HellermannTyton premium printer TT4030 prints high definition graphics such as 2d barcodes, standard bar codes, numbers and text on adhesive labels and thermo plastics such as heat shrink and cable markers (Tiptags).

A colour LCD Touchscreen with modern user interface helps intuitive operation.

How to install a thermal transfer printer? And how does it work? Questions like these will be answered in the short tutorial video below. Watch now how to use the TT4030 thermal transfer printer easily:

The 300 dpi print head fulfils all standard requirements for printing bar codes, warning signs, logos and written information.

Optional premium quality accessories such as a perforator and cutter are designed to work seamlessly with the printer and will suit the most demanding needs.

Creation of professional looking industrial identification is simplified by the use of HellermannTyton label creation software TagPrint Pro 4.0.

Whether in stand-alone mode, as a PC application or in a network - the robust TT4030 printers can meet every requirement.

Benefits at a glance

Please have a look at our quick installation guide here.

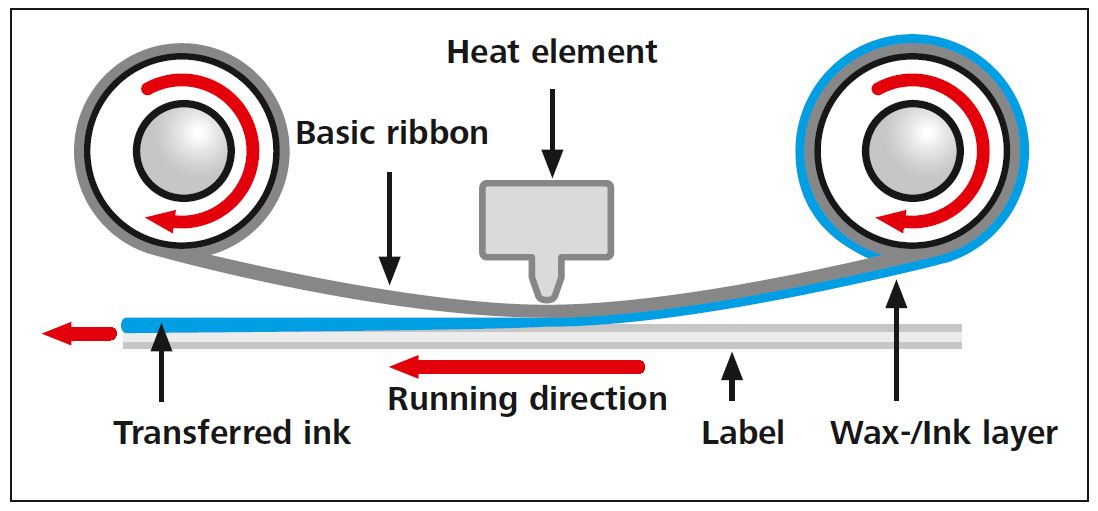

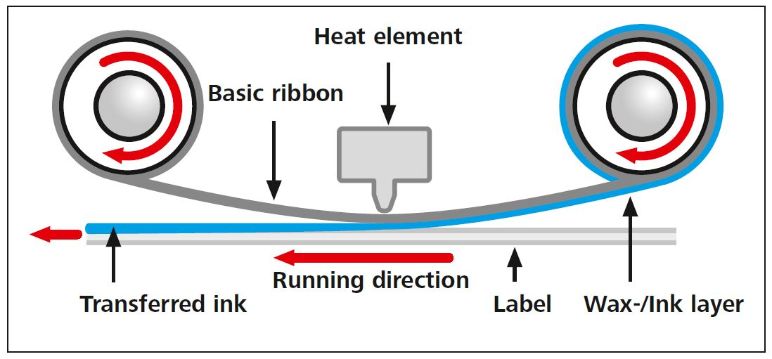

The thermal transfer print technology is based on heating up certain dots in the print head then transferring the ink very precisely from the ribbon on to the surface of the printed material.

All HellermannTyton thermal transfer ribbons consist of a special resin composition to maximise print performance.

In combination with HellermannTyton printers the ribbons ensure the highest print quality on all HellermannTyton thermal printable identification materials.

Benefits at a glance

Good print quality, high print speeds and the option of printing almost all backing materials permanently – these are the critical advantages of thermal transfer printing.

Its good readability, resistance and abrasion resistance allow thermal transfer printing to be put to use in applications where the print results from laser, inkjet or dot matrix printers are not satisfactory.

The advantages at a glance

More about our thermal transfer printing system solutions can be found here in this brochure.

Heated dots strike a special colour ribbon, the thermal transfer film, which transfers liquified colour ink at exactly that point onto the backing material (labels, tubes, rating plates).

HellermannTyton printers use what is known as “thin film technology”, in which the very brief liquid phase of the ink produces faster print speeds and better and more precise images than with the “thick film technology” formerly used.

Moreover, the linear orientation of the labels or of the heatshrink tubing makes it possible to print on demand. The printing is then carried out as required. This is especially useful in the production of rating plates in series production.

In thermal transfer printing, the print image is defined by the three components: printer, label material and thermal transfer film (colour ribbon).

Direct thermal and thermal transfer uses a thermal printhead that applies heat to the surface being marked.

Thermal transfer printing uses a heated ribbon to produce durable, long-lasting images on a wide variety of materials.

No ribbon is used in direct thermal printing, which creates the image directly on the printed material.

Direct thermal media is more sensitive to light, heat and abrasion, which reduces the life of the printed material.

Thermal transfer printing is not the same as direct thermal printing. We show you what the difference is and what advantages thermal transfer printing has. We also introduce you to our newest family member, the TT431. Learn more now, here in this video:

Check the heat settings (darkness) in the software. If the temperature is too high it may tear the ribbon.

Print a large black field on a high heat.This will help to remove all of the dirt.

The print head is damaged or dirty. Use spot clean pen or an alcohol solution. Refer to the printer manual.

Check that the reel of material is not sitting on the base of the printer and causing drag. If the reel is too big it can rub against the ribbon. Also if the reel is fixed too tight it can contribute to this issue. For large reels please use an external reel holder.

There is too much heat or too much pressure on the print head.

Refer to the user manual for a new label design.

Before disconnecting the printer from PC please “Safely Remove Hardware and Eject Media”. Best option is to use an Ethernet connection.

This is probably caused by selecting “continuous sensor” when you really need the gap sensor.

This is probably caused by selecting the incorrect sensor.

This may be an issue with the template. Please check the label and page dimensions. Refer also to the properties box in TP3.

A detailed guide to solve problems with our TT430 and TT4030 printers is summarized in our FAQ printer troubleshooting document.

To complement the range of printers and various marking materials in different sizes HellermannTyton offers the intuitive label design software TagPrint Pro. With the help of TagPrint Pro you can quickly and easily design your labels from scratch or per implemented Wizard. You can print single jobs but also batch print to either one or more printers at the same time.

Benefits at a glance:

TagPrint Pro has a wide range of data import capabilities, including XMT, CSV and ODBC, which will refresh automatically, or in the case of Excel, just open directly in the program. With TagPrint Pro, you can view object properties, data and actual label layout at the same time.

HellermannTyton Print Automation is the powerful workflow assistant built into TagPrint Pro label design software. It allows one-step printing of label jobs – even multi-label groups – to one or more printers simultaneously.

Instead of manual data entry, the individual print jobs are simply sent by the scan of a barcode. This ensures less susceptibility to errors and speeds up your production significantly: Compared to traditional workflows, you can print your labels up to 23 times faster.

For software & drivers please see our download area:

| Material | Label type |

TT4030DS |

TT4030 |

TT430 |

TT431 |

Ribbon |

| TCGT |  |

|

||||

| TULT |  |

TTRC+ TTDTHOUT TTRW TT822OUT8 |

||||

| TULT DS |  |

TTDTHOUT | ||||

| TLFX |  |

TTDTHOUT | ||||

| TLFX DS |  |

TTDTHOUT | ||||

| TDRT |  |

TTDTHOUT | ||||

| TDRT DS |  |

TTDTHOUT | ||||

| THTT |  |

TTRHT | ||||

| THTT DS |  |

TTRHT | ||||

| TLFD DS |  |

TTDTHOUT | ||||

| TIPTAG HF | - | TTDTHOUT | ||||

| TIPTAG PU | - | TTRC+ | ||||

| TIPTAG MC | - | TTDTHOUT TTRW |

||||

| TAGUL | - | TTDTHOUT | ||||

| TAGPU | - | TTRHT | ||||

| TAGLF | - | TTDTHOUT | ||||

| TAGDR | - | TTDTHOUT | ||||

| TAGHT | - | TTRHT | ||||

| Helatag 896 |  |

- | TT932DOUT | |||

| Helatag 323 |  |

- | ||||

| Helatag 892 | - | TT822OUT | ||||

| Helatag 1216 | - | TT822OUT | ||||

| Helatag 1220 | - | TT822OUT TT122OUT |

||||

| Helatag 1221 | - | TT822OUT TT122OUT |

||||

| Helatag 1204 | - | TT822OUT | ||||

| Helatag 1206 | - | TT822OUT | ||||

| Helatag 823 | - | TT822OUT | ||||

| Helatag 1208 | - | TT822OUT | ||||

| Helatag 951 | - | TT822OUT |